Solid Tantalum Capacitors: MnO2 vs. Polymer Cathodes for Optimal Performance in High-Reliability Military and Space Applications

Solid tantalum capacitors have a long history of proven performance in high-reliability military and space applications. But not all capacitors are created equal — even within the same class. As is the case with virtually all component technologies, materials matter. This paper will discuss the differences in performance and reliability between solid tantalum capacitors with manganese dioxide (MnO2) cathodes and those with conductive polymer cathodes.

Bell Laboratories introduced the first solid tantalum capacitors to market in the early 1950s. The first military specification for surface-mount tantalum capacitors (MIL-PRF-55365) was released in 1989 and introduced CWR09-style components. Since then, the product offerings governed by this specification have expanded to include CWR19-style capacitors with an extended range of CV values and CWR29-style capacitors, which offer low ESR limits for all of the ratings in the CWR09 and CWR19 product categories.

In the late 1990s, KYOCERA AVX began offering COTS-Plus families of tantalum capacitor products with extended CV (Capacitance x Voltage) values and low equivalent series resistance (ESR). These commercial- or professional-grade components could then be up-screened (i.e., tested and reliability graded per military test methods and requirements) for use in high-reliability military and aerospace applications, often with lower costs and shorter lead-times than true mil-spec components. Then, in the early 2000s, KYOCERA AVX launched its first space-level tantalum product line, the SRC9000 Series, which includes both military QPL and COTS-Plus products and offers several advantageous features, such as 100% X-ray screening, statistical screening, DPA sampling, and functional/life testing on each batch. By 2008, the SRC9000 Series had become the basis for the introduction of the T-level space solutions introduced into the MIL-PRF-55365 specification, which — just like all of the other specifications that regulate the use of tantalum capacitors in high-reliability military and aerospace applications (e.g., MIL-PRF-39003, MIL-PRF-39006, MIL-PRF-49137) — is based on tantalum capacitors with MnO2 cathode technology.[1]

Tantalum capacitors with current-conducting polymer cathodes, rather than MnO2 cathodes, have been around since the 1990s and offer a number of performance advantages over MnO2 variants. However, although polymer cathode tantalum capacitors are included in some DSCC drawings, there are no military specifications for these products, as the advantages they offer come with serious trade-offs in terms of reduced long-term reliability, the introduction of wear-out mechanisms, and variability in parametric performance under environmental stress.[2]

[2] For more information about polymer capacitors, please refer to “Basic Guidelines for Conductive Polymer Capacitors.”

Solid tantalum capacitors have varying degrees of storage and handling requirements. Product families and/or certain cases sizes within them are designated with a moisture sensitivity level (MSL) that determines which environmental conditions (e.g., temperature and humidity) are suitable for product storage and handling prior to PCB assembly. Tantalum capacitors with MnO2 cathodes are generally classified as MSL 1, with some MSL 3 ratings for parts with larger internal volumes, while virtually all non-hermetic polymer products are defined as MSL 3 or higher despite the fact that the porous anode structure responsible for moisture pickup potential is the same for both polymer and MnO2 tantalum capacitors. This discrepancy between the MSL classifications for solid tantalum capacitors with MnO2 and polymer cathodes is due to the wear-out mechanism that is only present in the latter and subsequent degradation in long-term performance.

Tantalum capacitors that aren’t stored according to product recommendations and are allowed to absorb excessive amounts of moisture can suffer from “popcorning” effects when subjected to reflow temperatures during PCB assembly. “Popcorning” occurs when the moisture within the structure rapidly vaporizes, causing internal pressure and venting that can cause cracking in the external packaging material. Although it is generally accepted that tantalum capacitors with polymer cathodes are more sensitive to this than MnO2-based capacitors, KYOCERA AVX proactively removes all excess moisture from its MnO2 SRC9000 and MIL-PRF-55365 capacitors prior to packaging, supplies them in protective moisture-barrier packaging, and provides guidelines for product drying should the parts get exposed to moisture prior to mounting.

One critical benefit of MnO2 tantalum capacitors, and one of the primary reasons that they’re ideal for use in high-reliability and long-life applications, is that there are no known wear-out mechanisms for this technology. In fact, MnO2 tantalum capacitors that have been operating in applications for 30 years or more — since before the publication of the MIL-PRF-55365 specification even — continue to improve in leakage performance and reliability with age. Conductive polymer capacitors employ the same dielectric as MnO2 tantalum capacitors with the same reliability and long life characteristics, but the conductive polymer that replaces the inorganic manganese dioxide is sensitive to humidity and oxidation, which can cause long-term parametric changes. Improvements have been made to the packaging of conductive polymer capacitors and have successfully alleviated some of the concerns, enabling them to meet automotive-grade environmental requirements including AEC-Q200, but beyond this, wear-out of the polymer material will continue. Hermetically sealing these polymer devices is currently the only true means of preventing environmental wear-out mechanisms caused by moisture ingress and oxidation. KYOCERA AVX’s TCH Series, which was developed in partnership with the European Space Agency (ESA) for use in aerospace applications, offers hermetically sealed conductive polymer capacitors in two case sizes with various capacitance and voltage values.

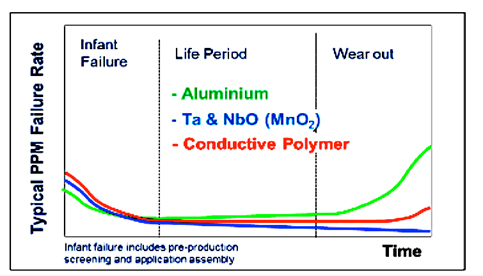

The graph below features the typical reliability curves for aluminum, MnO2, and conductive polymer capacitors and shows that MnO2 tantalum capacitors generally only experience early infant mortality failures and otherwise have an indefinite lifetime, whereas aluminum and conductive polymer capacitors always degrade over time. As such, extra care informed by a thorough understanding of expected end-of-life performance must be taken when designing such components into electronic systems.

Typical reliability curves for aluminum, MnO2, and conductive polymer capacitors support the fact that MnO2 tantalum capacitors generally only experience early infant mortality failures and otherwise have an indefinite lifetime, while conductive polymer capacitors have an additional parametric wear-out characteristic.

In addition to demonstrating sensitivity to certain storage, handling, and reflow mounting conditions, conductive polymer capacitors are also susceptible to effects of humidity within finished devices, hybrids, assemblies, and some end devices. Regardless of the circumstances surrounding its ingress, the presence of excess moisture initiates the degradation of the polymer cathode material. This degradation is then further accelerated by an application’s temperature and voltage characteristics (e.g., temperatures at or above 85°C at 85% of rated voltage), which leads to parametric capacitance loss.

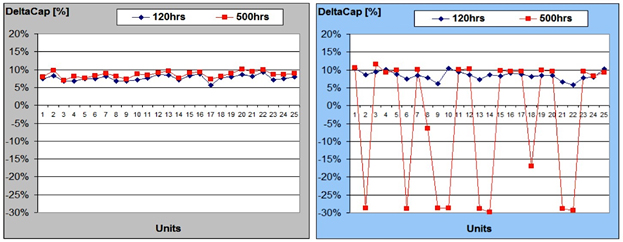

Alternately, the presence of moisture in an application or during assembled storage is not a concern for MnO2tantalum capacitors, as their cathode material is not degraded by the presence of moisture. The graphs below compare the typical performance of MnO2 and conductive polymer capacitors at 85°C, 85% relative humidity, and rated voltage for 500 hours. The MnO2 capacitors demonstrate consistent and predictable delta capacitance increases between 7% and 10% after 500 hours, while the conductive polymer capacitors have individual units that exhibit delta capacitance performance ranging from 12% all the way down to -30% and, were the graph to continue, even further degradation and additional capacitance loss over time.

These two graphs compare the typical performance of commercial tantalum capacitors with MnO2 cathodes (left) and those with conductive polymer cathodes (right) at 85°C, 85% relative humidity, and rated voltage for 500 hours.

Another side effect of moisture within conductive polymer cathodes is a loss of conductivity that can also affect dissipation factor and ESR.

Most commercial MnO2 tantalum capacitors have an operating temperature range extending from -55°C to 125°C, which aligns with most military and high-reliability application requirements, while many commercial polymer capacitors typically have an operating temperature range extending from -55°C to 85°C or 105°C. Conductive polymer capacitors designed for automotive and other high-reliability applications operate over the full -55°C to 125°C temperature range.

A study performed by NASA[3] in which standard polymers were stored at elevated temperatures ranging from 100°C to 150°C showed significant degradation of the material’s AC characteristics, which is consistent with stress test results for polymer capacitors. In less than 12 weeks at elevated temperatures, the material’s ESR began to increase and, after six months, the magnitudes increased two to 10 times the original values. The DC leakage (DCL) performance during this timeframe tended to decrease. When automotive-grade polymer components were subjected to high-temperature storage up to 150°C, the AC characteristics exhibited less shift, but DCL experienced significant movement up to two orders of magnitude (i.e., 100x) initial values. The DCL was, however, recoverable with extended time in room-temperature storage. Since there are multiple different types of polymer cathode materials applied to polymer capacitors, in addition to lot-to-lot and piece-to-piece variations, the effects of high-temperature storage or applications on performance can be variable.

The fact remains, though, that MnO2 tantalum capacitors do not exhibit any of these effects, instead reliably demonstrating stable performance for both AC and DC characteristics over indefinite storage times at temperatures up to 150°C.

Conductive polymer capacitors can also suffer from a phenomenon known as anomalous charging when parts are exposed to excessive drying or operation in a vacuum environment.[4] In these cases, at initial switch-on, components can exhibit high DC leakage current orders of magnitude stretching into the milliamp to amp range, which are significantly greater than in normal operation. These effects are further exacerbated by operation at lower temperatures, which can cause the capacitors to appear to short circuit for fractions of a second to durations of several minutes. This effect is not seen in all conductive polymers, as there are some high-voltage ratings that have been developed to eliminate this condition.

Anomalous transients can be especially detrimental to circuits when the capacitors are used in a filtering function, as DCL instability can result in unwanted noise within a system, which is contrary to the typical filtering goals of reducing ripple and smoothing signals. They can also cause permanent component damage or failure if the parts are subjected to sufficiently large charging currents, as a high-current condition at switch-on can result in a capacitor failing to charge quickly enough for the circuit to function within a specified time.

Once again, however, MnO2 tantalums are impervious to this phenomenon as well, instead exhibiting very consistent and predictable declining DCL performance in extremely dry, humid, or vacuum environmental conditions across the entire range of operating temperatures.

Solid tantalum capacitors recommend 50% derating in application, primarily due to transient and surge events that can be effectively overcome with appropriate circuit designs (e.g., characteristics including soft start, current limitation, circuit protection, etc.), while polymer capacitors generally only recommend 20% derating in application. It is, however, possible to reduce the required derating of solid tantalum depending on their design, test methods, and application conditions. For instance, KYOCERA AVX developed and patented the Q-Process™[5], which incorporates DCL testing using propriety methods at various temperatures and has been demonstrated to both improve reliability and significantly reduce — or even eliminate — the need for derating in many applications.

Originally, MnO2 tantalum capacitors designed for use in military applications employed exponential grading to establish a reliability grade and failure rate, which involved collecting samples from each product batch and subjecting them to long-term, 10,000-hour life tests to generate a large amount of component device hours. The pass/fail information was then used to determine the long-term reliability of the product line or family, and was therefore not lot specific, which left more room for variation. In addition, this grading process also imposed large costs on manufacturers in terms of supporting the required infrastructure and components.

As such, MnO2 reliability testing processes were transformed into what is known as Weibull grading — a burn-in/voltage conditioning process in which 100% of the capacitors are subjected to accelerated voltage and temperature (and, specifically, a minimum 1.3x rated voltage at 85°C) for a minimum of 40 hours. A 300-piece sample of the parts are monitored for failures after 15 minutes, two hours, and then 40 hours, and the distribution of those failures determines the calculated reliability grade (i.e., B, C, or D) for that particular batch of capacitors. While the sample is monitored for failures, the entire batch is then burned in at the same conditions and any units designated as failures are removed from the population. Historically, this process has been very successful at determining which batches of product are suitable for high-reliability applications.

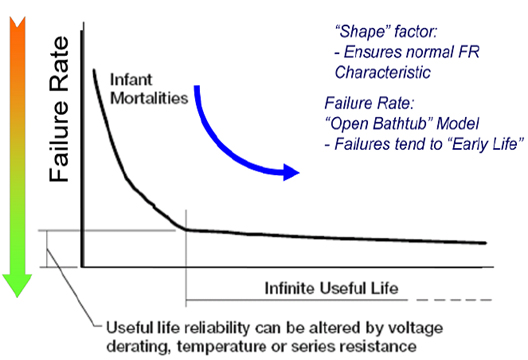

This open bathtub reliability curve illustrates MnO2 infant mortals removed during the burn-in/reliability grading process.

Considering that MnO2 capacitor failures tend to be infant mortals, meaning that most failures occur the first time they’re ever powered, Weibull grading is especially well suited to establishing the reliability of this technology, as it removes infant mortals to effectively shift the batch to the declining failure rate portion of the reliability curve. This same process, however, does not work for polymer capacitors, which tend to have a more latent failure mode due to wear-out and shifts in parametric performance. As such, there is currently no industry-reviewed and -approved alternative method for establishing the reliability of polymer components.

In addition to reliability grading, several other design and process developments have improved MnO2 tantalum reliability over time.[6] That with perhaps the greatest significance is the statistical screening of each production batch to process capability instead of simply applying catalog or even customer defined limits, as this process effectively removes any outliers, which are most to likely to cause issues in an application, from the normal population.

One of the most significant long-term reliability benefits of MnO2 tantalum capacitors, aside from their lack of any wear-out mechanisms, is their ability to “self-heal” or isolate defect sites. This phenomenon occurs when high leakage paths generate heat and transform the MnO2 into non-conductive Mn2O5, thereby isolating the defect site, preventing further deterioration, and returning DCL to nominal levels. Polymer capacitors have a similar self-healing mechanism, but it is less effective. Since polymer material is highly conductive, there is less heat generated by defect sites. As such, defect sites tend not to become fully isolated like those in MnO2 capacitors, which means that DC leakage tends to remain at an elevated state and results in increasing opportunities for further degradation.

Customer returns and reported failures for high-reliability MnO2 tantalums — millions of which are designed into critical new products, including life-sustaining medical applications such as pacemakers and defibrillators, every year — are currently at an all-time historical low. This declining field failure rate is attributable to continuous improvements in the design, processing, and screening techniques that reliably remove parts that may experience failures during customer processing and support better baseline components. Most of the customer claims issued today have to do with products that were held for a significant amount of time without regard to proper storage and handling prior to mounting or are simply cosmetic in nature, with no impact on the performance or reliability of the devices. Cosmetic defects are typically comprised of case cracks in the capacitor body caused by the thermal expansion of materials or thinner case walls designed to support the expansion of CV offerings and have no effect on MnO2 capacitor performance, lifetime, or reliability in application.

However, the same cannot be said about polymer capacitors. Although several enhancements have been made to polymer component packaging in recent years, the only true safeguard for preventing wear-out is to utilize hermetically sealed devices.

On occasion, voltage breakdown level is also touted as a means of assessing component reliability, but both MnO2 and polymer components have similar voltage breakdown performance (typically starting at two times the rated voltage), which is directly related to post-formation healing processes within the dielectric and has no direct effect on performance within an application.

One of the reported long-term reliability benefits of polymer capacitors is a benign failure mode when compared to MnO2 capacitors. When an MnO2 component fails, it short circuits, meaning that current to the component is unlimited and that device failure can become catastrophic, due to the fact that the MnO2 cathode system is an oxidation agent. The polymer capacitor cathode system removes this oxidation agent, but can still fail via short circuit, and while this may not have as catastrophic of an effect as the failure of an MnO2 capacitor, unlimited current to a shorted polymer capacitor can still result in significant local heating.

One of the biggest advantages of polymer components is their extremely low ESR values, which are down in the single-digit to tens of milliohms range. While standard MnO2 components do have higher ESR characteristic, the availability of a multianode construction style developed specifically to reduce ESR effectively bridges much of the gap between these two technologies. KYOCERA AVX’s TBM SRC9000 Series ultralow-ESR MnO2 multianode tantalum capacitors, for instance, provide ESR limits down to 18mΩ and have been actively designed into numerous aerospace- and space-level applications over the past 10 years, throughout which there has never been even a single reported error or field failure. The significant success, impressive performance, and long-term reliability of this series is perhaps best evinced by its employment in the Mars Curiosity Rover’s ChemCam system, which featured 630 TBM Series capacitors and energized them well more than half a million times between the rover’s Mars landing on August 6, 2012 and its death on February 13, 2019.

MnO2 tantalum capacitors have some of the lowest DCL levels available and both regularly and remarkably outperform published limits. For example, while typical military-grade components specify leakage levels of 0.01 CV, high-reliability MnO2 components normally exhibit process capabilities extending from 0.001 CV to 0.0025 CV. All high-reliability MnO2 capacitors produced by KYOCERA AVX, for instance, are subjected to rigorous conformance testing screening protocols to ensure that customers receive components within three standard deviations (i.e., sigma) of process capability, which is significantly below both the specification limits and the intrinsic capability of non-hermetic styles of polymer components.

Conversely, polymer components have published DCL values ranging from 0.1 CV to 0.05 CV, but without the same significant improvements in actual performance, which results in DCL performance that’s 5–50x worse than that of comparable MnO2 components.

Lastly, the screening limits used when electrically testing capacitors are also of critical importance. KYOCERA AVX’s SRC9000 space-level components receive statistical screening for both ESR and DCL to achieve a tighter distribution within the population and remove outliers. A three-sigma limit is established for each batch of components and utilized to remove individual units that, while still well below published limits, are outside of the normal population in order to provide a more homogenous population and further improve performance.

Below is a table outlining the general differences in ESR and DCL performance between various groups of components.

Parametric Comparison of Typical Space-Level Performance

| Lowest ESR Available Large Case Sizes (mΩ) | DC Leakage Catalog | DC Leakage Performance | |

|---|---|---|---|

| MnO2 Tantalum | 65–500 | 0.01 CV | 0.0025 CV |

| Multianode Tantalum | 18-100 | 0.01 CV | 0.0025 CV |

| Polymer | 5-250 | 0.1 - 0.05 CV | 0.05 CV |

Due to known wear-out mechanisms and instability in AC or DC performance across electrical and environmental conditions, tantalum capacitors with polymer cathode systems are not recommended for long-term use in all high-reliability applications. Tantalum capacitors with MnO2 cathode systems, on the other hand, have a long history of extremely stable performance over decades of employment in demanding, harsh-environment military and space applications, which squarely establish it as the preferred technology for long-term use in high-reliability, mission- critical military- and space-level applications.

Summary of Performance Differences Between MnO2 Tantalum and Polymer Tantalum

| Feature / Performance | MnO2 Tantalum | Polymer Tantalum |

|---|---|---|

| High-Temperature Storage | No Concern | Potential for Degradation of AC Characteristics |

| Moisture Sensitivity Level | MSL 1 to MSL 3 | MSL 3 |

| Humidity Sensitivity, Post Mounting | No Concern | Wear-out Accelerated by Temperature and Voltage |

| Anomalous Transients | No Concern | Occurs Under Dry Conditions |

| Oxidation | No Concern | Wear-out Accelerated by Temperature |

| ESR | Low ESR in Standard, Ultralow ESR in Multianode | Ultralow ESR |

| DCL | Ultralow | Medium to High |