Optimizing IoT Devices for GEO NB-NTN Hybrid Connectivity Written in Collaboration with: Telefonica Germany, Viasat, & Skylo Abstract: The introduction of technology innovations is always fraught with lead times, a “learning curve” that the industry needs to understand how best to use and integrate the new capabilities into viable and profitable products or services. This whitepaper introduces the technical aspects involved in designing and optimizing IoT devices for Narrow-Band Non-terrestrial Networks (NB-NTN). This is a standardized 5G technology which adapts the terrestrial Narrow-Band IoT (NB-IoT) protocol for connecting remote, constrained IoT devices to ground-based cellular networks via orbiting satellites. Specific focus is placed on services intended to communicate over Geostationary Orbit (GEO) satellites and terrestrial networks. Numerous topics will be

Technical Articles / Whitepapers

Ripple Current: An Increasingly Relevant Test to Complement Design Considerations Written By: Vincent Mao, Joe Hock, Caleb Winfrey Abstract: The world is shifting towards electrification with electric vehicles (EVs), renewable energy, and smaller, more powerful, but efficient, system-on-chips (SOCs) as both signal and power integrity across different environments become a concern. The ripple current test is usually required to assess device performance up to 20°C above room temperature. This overview focuses on the test setups used to cover three ESR tiers (low, medium, high, respectively) for applications from signal integrity to microwave/RF. We present initial results and procedures to collect and analyze data as well as considerations for performance impacts with mounted parts. Ongoing challenges are also discussed.

C0G High Voltage MLCC in DCDC and OBC Applications Written By: Robert Lu Abstract: This white paper discusses the advantages of C0G high voltage MLCCs when compared to film capacitors. Capacitance stability is a crucial element when choosing the right resonant capacitor for resonant circuits. Minimum variations with shifts in temperature, voltage, and frequency fluctuation are desirable. Although film capacitors provide a good option for certain applications, advances in MLCC technology have improved the performance of other capacitor dielectrics. In DC-DC/OBC applications, C0G High Voltage MLCCs can represent a more suitable option when compared to film capacitors, maintaining minimal capacitance variation with temperature and low dissipation factor at high frequencies.

Assessing the Benefits of Tantalum Capacitors in Electronic Detonator Applications Written By: John Lee Abstract: Electronic detonators have revolutionized explosive applications by allowing precise control over detonation timing, increased safety, and improved efficiency. Since capacitors are indispensable in electronic detonators, choosing the right capacitor is crucial for ensuring system robustness. The emergence of Tantalum (MnO2) Capacitors has been a gamechanger. Tantalum capacitors offer excellent electrical characteristics and robust reliability, making them suitable for electronic detonator applications. This whitepaper delves into essential parameters for choosing capacitors, focusing on the benefits of integrating Tantalum capacitors. Electronic detonators are devices utilized for initiating explosive charges. Unlike conventional fuse-based detonators, electronic detonators offer precise timing, increased safety, and improved performance in various mining, construction,

IoT Satellite Connectivity Enabled by Small Ceramic Chip Antennas – Case Study Written By: Maria El Bacha & Carmen Redondo (KYOCERA AVX) | Brett Collis (EchoStar Mobile) Abstract: Traditional perceptions of satellite communications often conjure images of large antennas facilitating one-way communication. However, with the evolution of IoT satellite technologies, bidirectional communication and compact embedded antennas have become feasible, revolutionizing connectivity in remote and challenging environments. This paper explores the capabilities of EchoStar Mobile LoRaWAN® over satellite, highlighting the potential for bi-directional communication and the integration of KYOCERA AVX small chip embedded antennas within IoT devices. Through a case study, we demonstrate the functionality and effectiveness of this antenna solution in real-world applications, showcasing their role in advancing IoT satellite

Card Edge Connectors for Lighting Applications Written By: Raul Saucedo Abstract: For more than 50 years, the PCB edge connected circuit card has been a mainstay in both desktop and server computers. The traditional arrangement of backplanes and motherboards with numerous card edge slots allowed for configurability and expansion in a rapidly advancing industry. The natural result was an evolution of edge card connector technology focused on higher contact densities and improved electrical performance to try and maximize speed and throughput. More recently, card edge connectors have taken on a new role in the world of solid state lighting (SSL) as the LED has become the dominant source of efficient illumination. LED lighting can be split into two broad categories:

Connectors for Medical Device PCBs Written By: Ajay Saini Abstract: The term “medical device” covers a broad spectrum of electrical equipment, ranging from small implantable stimulators to room sized MRI machines. This equipment is typically broken down into three classes based on the safety implications of possible failure modes. Class I devices present minimal potential for harm to the user and are often simpler in design. 47% of medical devices fall into this class, and 95% of these are exempt from any special regulatory oversight. Once appreciable safety concerns come into play, the device is elevated to Class II status. Class III devices require the utmost scrutiny and are subject to intense regulatory oversight, putting them into a category of

Surface Mount Capacitors for DC-DC Converter Applications Written By: Naotaka Hata Abstract: Tantalum, polymer, ceramic, film, and aluminum capacitors each offer a different set of operating and performance characteristics. Choosing the proper capacitor when designing DC-DC converters requires a careful understanding of these differences. High voltage front-end connections to the power source typically rely on aluminum capacitors, while intermediate step-down voltages often look towards the tantalum and ceramic families to take advantage of volumetric efficiency. The final load decoupling and bypass capacitors are generally found in the ceramic and film families. Surface mount (SMD) capacitors can be constructed using several different technologies to achieve a range of voltage tolerance, bulk capacitance, and parasitic device characteristics. As shown in Figure 1,

Laser Direct Structuring (LDS): Working Principles and Benefits for RF Applications Written By: Youssef Laamimat Abstract: The growing prevalence of electronic devices presents a challenge to numerous industries and markets. Addressing the industry’s need for lighter and more compact components, LDS stands out as an excellent choice. In addition, it accelerates prototype production and streamlines time-to-market. Laser Direct Structuring (LDS) technology is a revolutionary approach offering a streamlined and efficient process for creating complex 3D circuits on a myriad of substrates. LDS technology is ideal when more curves are needed or less 3D volume is available. In RF applications such as antennas, this allows the manufacture of highly intricate designs, reduces assembly costs of having the antenna outside the device,

Controlled Self-Healing of Power Film Capacitors Written By: Kevin Cho Abstract: In high voltage, high energy applications such as electric trains and solar power grids, the safety and reliability of capacitors are paramount. Catastrophic failures and associated explosions or fires are unacceptable. Just as importantly, service lifetime and predictability for optimizing up-time are critical to the product’s success. Film capacitors with controlled self-healing are the ideal solution to these challenges and can be obtained in various sizes and technical specifications. This whitepaper discusses the distinctions between aluminum electrolytic and metal film capacitors before considering some distinct advantages of film capacitors and the self-healing properties of metallized film capacitors.

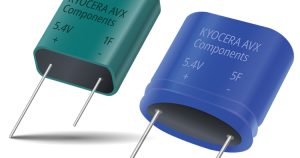

Safety Considerations for Acetonitrile SuperCapacitors Written By: Akihiro Kado Abstract: Advancements in SuperCapacitor design and manufacturing have made them a mainstay component in power supplies and backup systems that require high power density output. SuperCapacitors have now become commonplace components in many areas of modern electronic design. They bridge an important gap between batteries – used for high density energy storage, and electronic capacitors – for local power supply stabilization and decoupling. SuperCapacitors offer the unique ability to provide large amounts of power for short periods of time. For this reason, they have found a home in applications such as electric vehicles, uninterruptible power supplies, and data storage devices. A wide variety of SuperCapacitor structures and materials have been developed,

Radiation Tolerance of Tantalum Polymer Capacitors Written By: Krystof Adamek Abstract: Environments rich in ionizing radiation create a particularly difficult functional challenge for electronic components. Spacecraft, nuclear reactors, particle accelerators, and hardened military equipment (to name a few examples) demand that their electrical systems operate correctly, even in the presence of high energy particles, photons, electrons, neutrons, protons, and the like. Such radiation adversely affects electronics in two ways: fundamentally damaging the constituent materials, and creating transient electrical signals that can impede functionality. Mechanisms of radiation induced failure in semiconductors and other active devices have been well-studied, and methods for overcoming or preventing these failures have been developed. Passive devices like inductors, resistors, and capacitors, on the other hand, are

Advantages of SuperCapacitors for Power Constrained Backup Written By: Johnson Jiang Abstract: In most energy storage scenarios, the tradeoffs between power density and energy density quickly come to the foreground. This is best illustrated in the automotive industry, where power density directly translates to acceleration and driving performance, while energy density translates to the total range achievable on a tank of gas or, for an electric vehicle, on a single recharge cycle. This is true across almost every application, from wearable electronics to microgrid power networks on a college campus. This whitepaper from KYOCERA AVX will explore the advantages of SuperCapacitors, circuit level, uninterruptable power, and microgrid considerations, and the benefits that make them a more reliable option than traditional

Failure Mode Comparison of Tantalum and Niobium Oxide Capacitors Written By: George Zhang Abstract: The automotive industry has become highly dependent on advanced sensing and computing. Starting in the mid-twentieth century, the development of dense, reliable, and stable capacitors has been instrumental in advancing high speed computing and high performance electronics. The demands on these capacitors have increased substantially, requiring high-temperature tolerance, harsh environmental reliability, and ever-decreasing parasitic parameters such as equivalent series resistance (ESR) and inductance (ESL). Tantalum and niobium oxide capacitors have been two of the most notable contenders to meet these requirements. Though similar in construction, their failure modes are nuanced and require a careful understanding to ensure a successful design for a particular application.

The Principles of Varistor Selection Written By: Teddy Won Abstract: A varistor is an electronic component used to suppress transient voltages to protect electronic circuits. The behavior of varistors in a circuit is similar to TVS diodes, but they are entirely different in design, materials, and construction. There are many kinds of varistors on the market suitable for various applications, making choosing the right one to protect a given circuit challenging. KYOCERA AVX multilayer varistors, with a unique high-energy multilayer construction, provide state-of-the-art overvoltage circuit protection and protection from voltage transients caused by ESD, inductive switching, automotive-related transients, NEMP, lighting, etc. KYOCERA AVX multilayer varistors also provide EMI/RFI filtering in the off-state, which can replace the need for additional EMC

Properties and Characteristics of Crystal Units Written By: Wataru Muraoka Abstract: Numerous devices in people‘s lives today are becoming more sophisticated. As a result, the number of crystal devices installed is increasing. For example, with the evolution of autonomous driving, we are using crystal devices for many functions such as sensor systems to detect distance, camera systems to capture images, image processing systems to process captured images, and communication systems to communicate many of those digital data in and out of the vehicle at high speed. Crystal Units are a piezoelectric element which produces electricity on the surface when mechanical pressure is applied, and when electricity is applied it vibrates in a certain manner. A Crystal Unit is a product